TH410-A70II Ladle Slide Gate Mechanism

Home > Products > Ladle Slide Gate System > TH410-A70II Ladle Slide Gate Mechanism

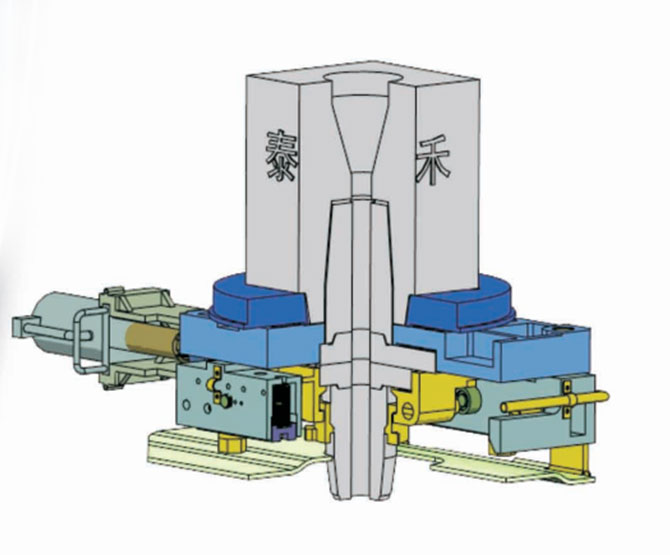

TH410-A70II Ladle Slide Gate Mechanism

TH-AII type ladle slide gate mechanism include TH310-A55II、TH359-A60II、TH410-A70II,and the introduction of TH410-A70II.

Description

1.Type explanation of TH410-A70II

● TH:represents the mechanism is designed by TaiHe

● 410:represents the standard length of the slide plates is 410 mm

● A:represents the structure of the mechanism is up /down to make the gate opened or closed.

● 70:represents the maximum standard plug hole of the slide plates is 70 mm

● Ⅱ:represents the mechanism is the second generation

2. The main technical parameters of TH410-A70Ⅱmechanism

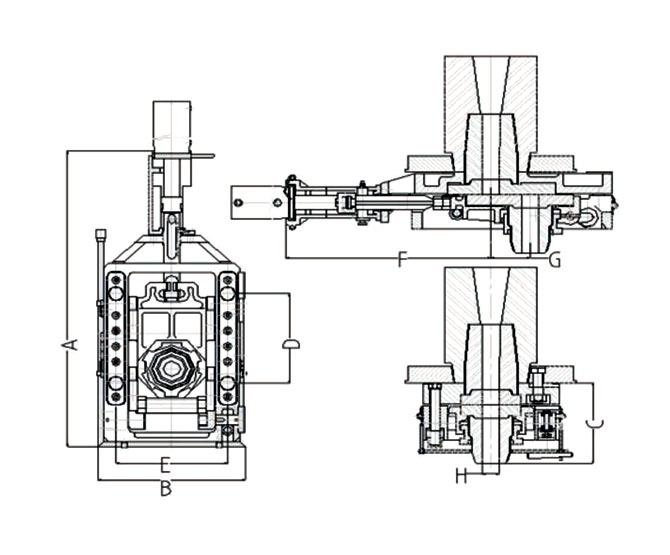

● Dimensions: 1240×520×346 (L × W × H)

● Service life: ≥2000 heats

● Stroke: 150 mm

● Spring type: disk spring

● Spring quantities: 6 x 2 groups

● Operating temperature of spring: ≤450 ℃

3.Construction and principle of TH410-A70Ⅱ

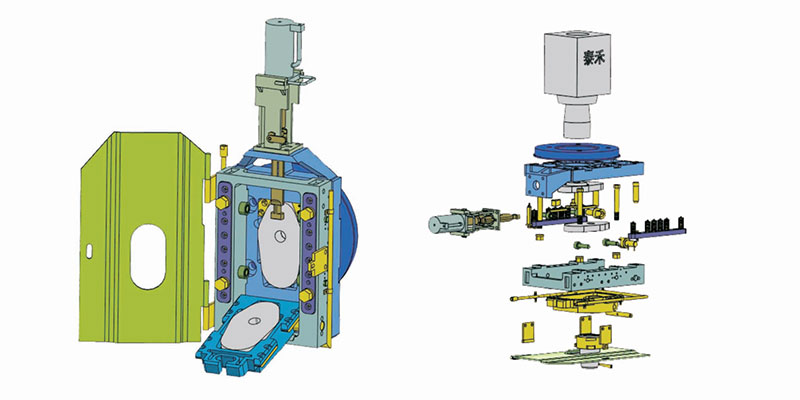

TH410-A70Ⅱ ladle slide gate mechanism comprises: housing, support, slider, springs component and cylinder bracket.

The combination of the upper and slider plate is a boundary, housing is fixed on the base of the bottom of the ladle, support is opening part, and slider is active part. Ladle nozzle and upper plate are fixed in the housing and slider plate and exchangeable nozzle are fixed in the slider, slider component can slide in the support component. A uniform and constant interfacial pressure is established through the spring component in the plate boundary. Under the working condition, support and housing are hinged together through the safety pin hinge. Pressure is transmitted to plate boundary through the support slide bar and the slider slide bar. Driven by the hydraulic cylinder, thereby achieving the flow control.

4.Technical Features of TH410-A70Ⅱ

4.1 The pressure area is constant. Slider is within the working stroke, The four pressure points where the mechanism pass the pressure to the slider is unchanged and is always around the center of the ladle nozzle.

4.2 The mechanism is of frame type and elastic compression structure, using disk spring to compress slide plate. The structure is reasonable and springs have long service life. With such kind of structure, the slide interface is easy to establish a constant and uniform pressure state and is not affected by high temperatures and human factors. Changes in thermal expansion caused by temperature changes and workers operating habits are absorbed by the spring when it is on service. The slide interface is always in a constant and uniform pressure state, which make the mechanism running more smoothly and security.

4.3 Adopting the advanced gate structure. Disassembly of refractory is very convenient and easy operation.

4.4 The mechanism has air cooling device to enable more secure and reliable operation and long spring service life.

4.5 It can satisfy the use requirements of the many times and continuous slide of the slide plate.

Product number

| Number | A | B | C | D | E | F | G | H | Applicable ladle |

|---|---|---|---|---|---|---|---|---|---|

| TH310-A55II | 1080 | 509 | 318 | 400 | 246 | 669 | 110 | 55 | 30-50 |

| TH359-A60II | 1217 | 539 | 319 | 300 | 290 | 759 | 120 | 60 | 50-80 |

| TH410-A70II | 1240 | 520 | 346 | 300 | 320 | 781 | 150 | 70 | 80-150 |

Get in Touch

New Strategies and Business Decisions

Please contact us, if you need any solution of Ladle Slide gate system, Ladle slide gate,Tundish nozzle, Slide Gate, Refractories.