TH90-ZK20Q Tundish Calibrated Nozzle Changer

Home > Products > Tundish Calibrated Nozzle Changer For Billet Stopper System > TH90-ZK20Q Tundish Calibrated Nozzle Changer

TH90-ZK20Q Tundish Calibrated Nozzle Changer

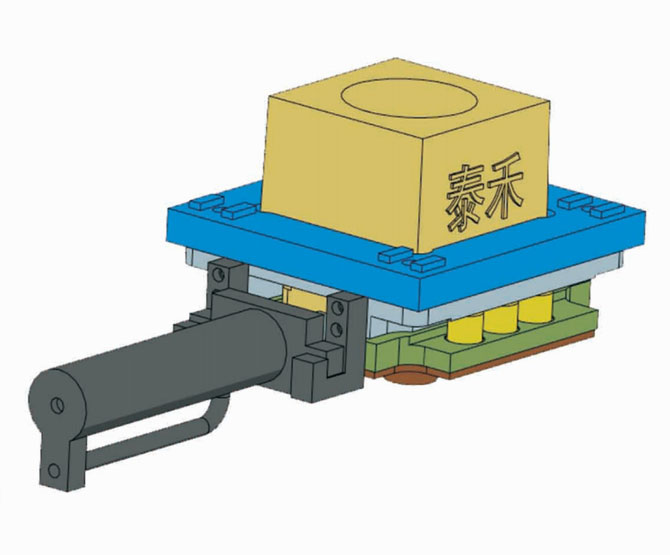

TH90-ZK20Q tundish calibrated nozzle changer is used for casting in steel mill. The gate is installed in the bottom of the tundish during production processing , it can change the nozzle plate in a very short time (about 0.5s).

Description

1. TH - ZK90 name and type

TH—— Represents designed by TaiHe

90—Represents working face width (mm) of nozzle plate

ZK—Represents as the tundish calibrated nozzle changer

20——Represents the largest plug hole (mm) of upper fixed plate

Q ——Represents the gas spring

2. Main technical parameters of TH90 - ZK20Q

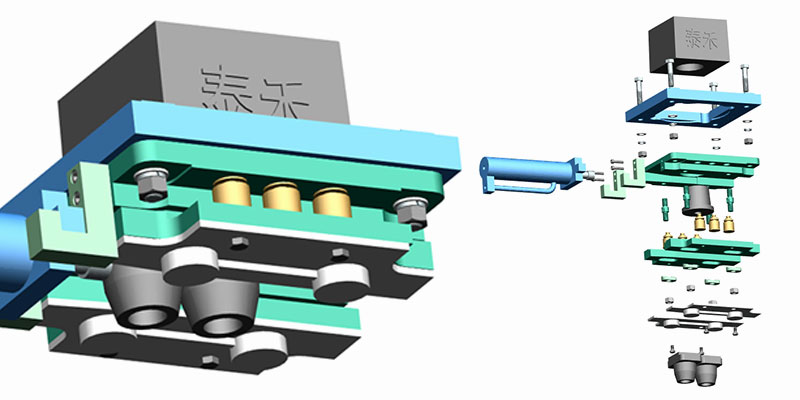

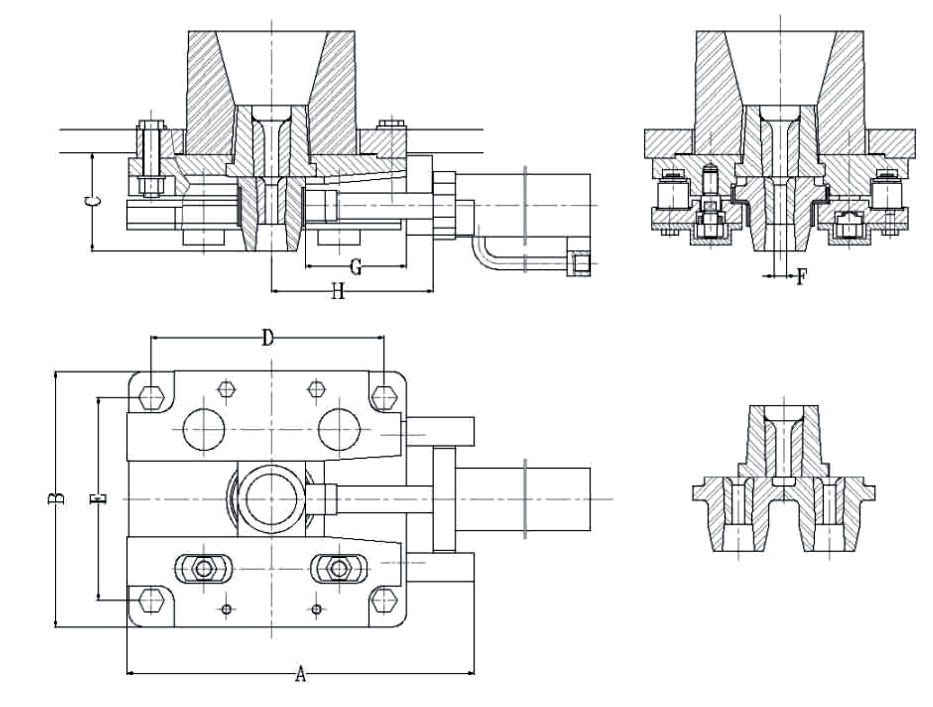

● Dimension: 460 × 340×131 (l ×w × h)

● Installation size: 310× 270

● Install bolts: M20×90 (4)

● Spring type: inert gas spring

3. Structure and principle of TH90 - ZK20Q

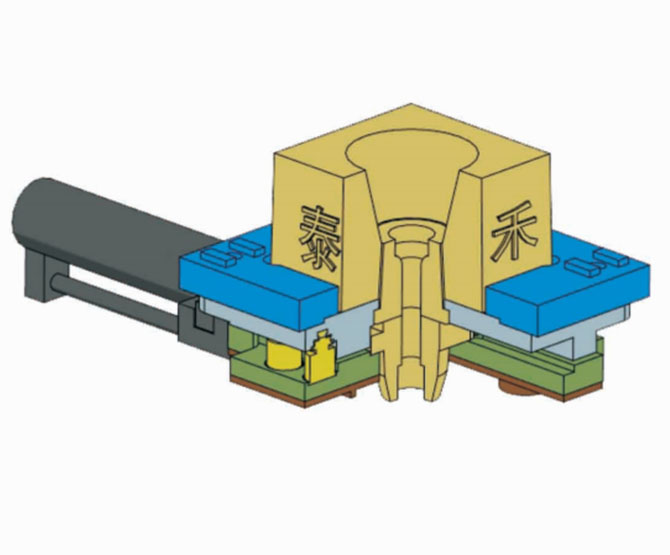

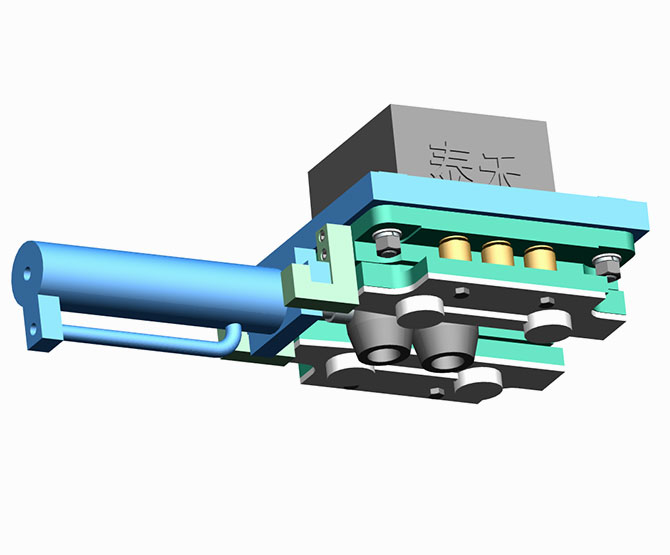

The tundish calibrated nozzle changer is mainly composed of the housing, guide plate, splash protection and corresponding refractory, etc. Housing is fixed in the bottom of the tundish, the upper fixed plate is installed in the housing firmly, left and right guide plates and housing are assembled into an organic whole through the guide rod. There are slide ways on the left and right guide setting for the nozzle plate sliding, having 3 springs on both sides of the nozzle, the pressure of the spring transmits to nozzle plate through the guide for make the upper and nozzle plate working face fit closely, sizing nozzle plate slides in guide slide way through hydraulic cylinder for powering source , so as to realize the quick replacement of nozzle plate smoothly.

4. Main characteristics of TH90 ZK20Q

4.1 In the case of casting smoothly in tundish, the gate can change nozzle plate quickly many times online, there are no limit of nozzle plate life in tundish online continuous casting time, it can improve the service life of the tundish significantly.

4.2.It can replace the nozzle plate with different diameters online to adjust the flow velocity in the tundish, and implement appropriate matching with the casting speed and make the steelmaking and continuous casting keep the same pace.

4.3 when one strand of the mold occurs fault, you can use the blind plate to river closure and maintain the mould online. Therefore, after failure recovery, the replacement of a new nozzle plate need be finished quickly so that the casting can start again, to meet the continuous casting process requirements.

4.4.When the tundish stop teeming or other failures, you can replace the blind plate to river closure immediately, and make corresponding treatment for the tundish.

4.5 Gate design considers the effect of temperature on the elastic element, for this reason, it uses the unique design for heat insulation and reasonable spring arrangement, so that make the spring far away from high heat area, minimizing thermal influence. It enables the use of gate more safely, reliably, and has a longer service life.

4.6 The main body of the gate uses heat resisting refractory, to avoid the shortcomings of welding steel structure which includes short working time, easy to deformation and the high accident rate, so it has a long service life.

4.7 It has scientific and reasonable structure design, operation and maintenance is simple and convenient.

Get in Touch

New Strategies and Business Decisions

Please contact us, if you need any solution of Ladle Slide gate system, Ladle slide gate,Tundish nozzle, Slide Gate, Refractories.